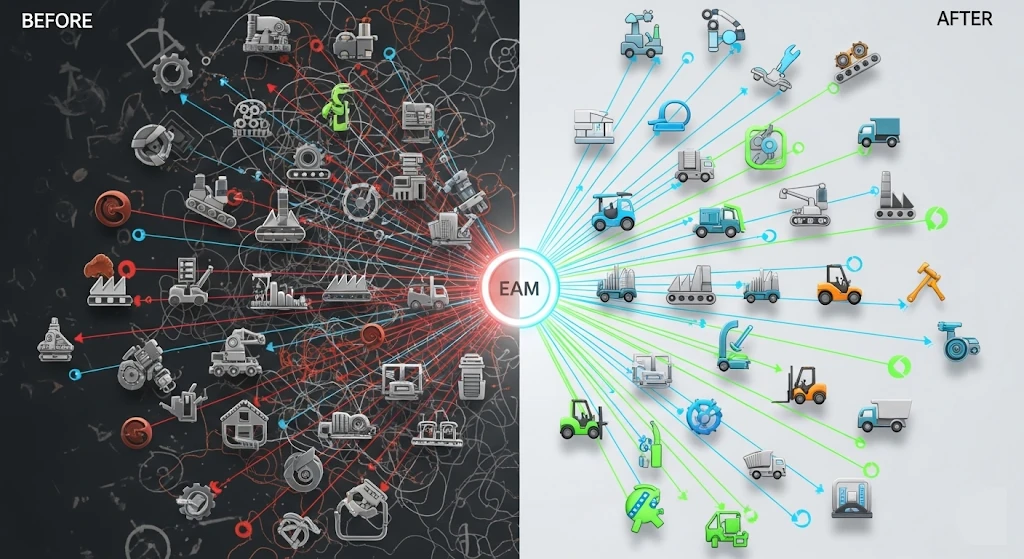

EAM software stands for enterprise asset management software that helps any company manage its physical assets from acquisition to maintenance and up to retirement. It organizes all the functions in the entire asset lifecycle (work order management, maintenance, inventory, purchasing, compliance, analytics, etc.) into one application.

EAM decreases the frequency of further repairs while increasing asset reliability and accountability. It enables organizations to better extend asset life, reduce downtime, enhance safety, and reduce the total costs of maintenance. In this guidebook, we will address the following: What is EAM, Why is it important, When will you use EAM, Core features, Best practices for implementation, Buying considerations, Advanced trends, and How to measure ROI.

Defining EAM Software

EAM is a system of record that collects and retains information about an organization’s physical assets (a structure, a piece of machinery, vehicles, equipment, etc.) across its lifecycle. EAM supports you in the following:

- Monitor asset performance from purchase to disposal

- Maintain performance schedules (reactive, preventive, condition-based)

- Manage inventory/spares to ensure parts are available

- Control procurement and accounting for your asset spend

- Uphold health, environmental safety, and regulatory compliance

- Provide insights using analytics and reports

EAM takes these capabilities that a CMMS (Computerized Maintenance Management System) has and puts additional emphasis on strategic planning and accounting of assets. EAM is important in a world of modern enterprises that manage some level of complexity around asset ownership.

What’s the business case for EAM?

- Increase Asset Uptime: Predictive maintenance will keep your assets from costly breakdowns.

- Improve Asset Life: Enhanced lifecycle by timing servicing.

- Optimize Maintenance Spending: Preventive and reactive actions are a balance to be struck.

- Enhance Compliance: Inspections, certifications, and readiness for audits can all be recorded.

- Enhance Workforce Efficiency: work order, scheduling, and mobility are streamlined.

- Support Sustainability: Monitor usage of energy and waste footprint.

EAM is the means by which an organization turns its liabilities of assets into data-driven, revenue-generating resources rather than a cost sinkhole.

When is EAM the right fit?

Asset-Intensive Industry

For example, anyone who works with complex physical assets in manufacturing, energy, mining, utilities, healthcare, transportation, and infrastructure.

High Cost of Downtime

We normally think of downtime as an inconvenience; however, if stoppages are happening in a high-risk situation concerning safety, like data centers or aviation industry stoppages that directly impact revenue. In such cases, list crawling through failure logs, vendor maintenance records, and historical breakdowns becomes critical to identify root causes and prevent recurrence.

High Compliance Needs

For example, companies operating and/or selling for industries that have strict environmental, safety, or financial regulations (like ISO, FDA, and EPA operate in.

Business Scale or Modernization

If you are transitioning to digital maintenance practices, organizations that have decentralized their field teams, or companies that have experienced vertical industry vendor and buyer growth and partnerships with industry-specific ERP/IIoT vendor solutions.

Core EAM Features

Asset Management & Hierarchies

Capture each asset’s specs, maintenance history, location, and ownership associated with the nested hierarchy (plant > line > equipment).

Work Order & Maintenance Scheduling

Create, assign, trust and track maintenance tasks (reactive – repair or replace, scheduled, condition-based)

Inventory & Spares Management

Maintain stock levels, auto-generate purchase orders and track usage and reordering.

Mobile Field Capabilities

Enable technicians to receive work orders, log work, upload pictures, and close work orders via tablets or smartphones.

Preventive/Condition-Based Maintenance

Set up time-based triggers or IoT sensor thresholds to generate work orders.

Procurement & Financial Integration

Enable the EAM to be integrated with ERP/financial systems to automatically capitalize a new asset, track depreciation, and automatically track the financials.

Reporting & Analytics

Display and visualize key metrics such as: MTBF (mean time between failures), MTTR (mean time to repair), cost per repair, and display dashboards and trend matters.

Compliance & Auditing

Create, manage and store inspection records and certificates, and log non-conformance for audit records.

Vendor & Contract Management

Track service level agreements (SLA), warranties, and vendors.

Enhanced Capabilities & Integrations

IoT & Predictive Maintenance

Attaching sensors measure asset vibration, heat, pressure, etc., and automatically create work orders in real time.

Cloud vs. On-Premise EAM

Cloud SaaS allows for quicker deployment, subscription payment methods, and easy updates. On-premise could be useful for sensitive data requirements or existing custom warehouses.

AI & Machine Learning

AI will analyze usage data and predict failures, optimize scheduled work, and automatically forecast spare part inventory.

Connected Systems

EAM will connect with ERP, CMMS, SCADA, BMS, BI systems, and mobile enterprise systems.

Field Service Management

Allows scheduling technicians dispersed across multiple geographical locations, optimizing dispatch for work order scheduling, and managing work across disparate locations.

Reasons to Have and Use EAM Solutions

Uptime: Decrease the time between breakdowns with proactive maintenance

- Asset Longevity: Plan to service assets to increase service life

- Cost Management: Decrease emergency repairs

- Compliance Efficiency: Reduce the effort for compliance reporting with documentation

- Visibility: Centralized and holistic view of asset health

- Operational Excellence: Improved planning, productivity of staff, and ISPs on the job

Help to translate assets into trusted & measured organizational drivers.

EAM Implementation Pain Points

Data Cleanliness & Migration

Asset records are incomplete or inconsistent, requiring data cleansing before upload.

Change Management

Technicians may be unwilling to accept any workflow changes – training and steering committees are great tools to recruit users to adopt new systems.

Some companies attempt EAM implementation using a waterfall model of project management, which can cause delays or inflexibility. For more agile adaptation, a phased approach or pilot-first strategy often works better.

Integration Complexity

Integrating an EAM with existing ERP, IoT platforms, or accounting systems requires careful architecture.

Workflow Standardization

For successful integration processes, the organization needs to agree on definitions for maintenance categories, task IDs, vendor protocols, etc.

Licensing & Costs

Be specific on the structure of dues and costs for deployment (user, asset, module) and for hosting (cloud vs on-premise TCO).

Best Practices for Successful EAM

- Piloting a site: Validating workflows in a pilot is essential before enterprise-level implementation.

- Cleansing Your Data: standard naming, a serial number, tagging locations, etc.

- Stakeholder Early Involvement: field technicians, finance, procurement, IT.

- Ongoing Training: hands-on training sessions, cheat sheets, and reinforcement workshop training.

- Building measurable KPIs: asset uptime%, preventive maintenance %, total cost per asset, regulatory or compliance %

- Dashboard usage: monitoring alerts, compliance due dates, asset maintenance warnings, etc.

- Iterate & improve: self-audits, monthly inspections and year-end performance review.

How to pick the best EAM Application for your needs

Vendor Evaluation Criteria

- These are some criteria for evaluating a vendor. Industry Fit: the vendor has a more advanced industry-matched domain expertise specific to your vertical (e.g., oil and gas vs hospitals).

- Scalability: be able to deal with larger inventories of assets and sites that are multiple sites.

- Using cloud options: flexibility of hosting with auto-updates

- Usability: need for mobile UX apps (e.g., simple click access work-order flow, translation support with languages/dashboards)

- Integration readiness: open APIs, connectors for ERP, IoT, CMMS apps, etc.

- Analytics: AI predictive, trend reporting, and dashboards

- Support and upgrades: agreed on SLA benchmarks, vendor user forums, maintenance packages

- TCO – all costs, including licensing and other implementation costs

Assessing ROI for EAM Investments

- Costs avoided from downtime (for example, 25 hours avoided/month * asset’s hourly cost)

- Savings from lower costs (fewer repairs, parts, overtime)

- Value of increased longevity of assets (delaying a capital expense to replace)

- Savings from regulatory fines (audit deadlines completed on time)

- Increased efficiency for users (less time spent on handwritten work orders)

- Combine into a financial business case with a very normal ROI expectation of 12-24 months.

EAM Trends to Watch

- The expanded adoption and integration of IoT sensors that enable asset classes to shift from fixed to predictive maintenance

- Adoption of AI-driven technology and digital twins: virtual twins of a real asset to allow better identification of usage and better maintenance scheduling.

- A new generation of data analytics-driven learning: predictive failure process and root-cause analysis using machine learning approaches

- Expanded enterprise applications: more acceptance for vendors to get visibility into the EAM tech, and the visibility available with the EAM tech

- User interface design for mobile-first environments: enabling field techs to obtain offline access with barcode/RFID scanning

- Democratisation of EAM: more reasonable pricing, deployment to SMBs, costs per asset per month trending downward, longer timeframes for delivery of value to newer and mid-market clients.

Enterprise Asset Management vs. CMMS

EAM covers the full lifecycle and financing; CMMS looks at reactive or scheduled maintenance. Companies may use CMMS as their initial approach in establishing an asset management structure when they have a more transactional and break/fix approach to maintenance. In contrast, organizations want to adopt a longer-term strategy to increase efficiency and optimize assets; they will require more comprehensive EAM capabilities.

Steps to be Taken to Start Your EAM Journey

- Cross-functional team (operations, finance, IT, and maintenance) set up

- Inventory and auditing of assets and workflows.

- Goals should be set against measurable performance indicators (e.g., % downtime, time to close work orders, cost per repair).

- Select a location for your pilot study

- Select your solution based on your needs and budget

- Prepare the data, customize your software, and train the staff

- Go live and start learning from your feedback

Conclusion

Enterprise Asset Management software is key to realizing operational effectiveness, cost efficiencies, compliance objectives, and asset intelligence in asset-intensive organizations. EAM creates a single operating center of physical assets by combining data, people, and processes. Whether you need to achieve less downtime, increased life of equipment, improved compliance, or strategic cost controls, EAM delivers measurable results. Selecting the right platform, engaging stakeholder support and committing to an ongoing improvement cycle, continually transform your assets to sustainably enable business.

Start with a pilot, measure results, and iterate wisely—EAM is not just software; it’s a strategic partner for delivering reliable, technology-led operations.

FAQs

Is EAM only for manufacturing?

No, EAM is leveraged in utilities, health care, transportation, facilities, oil & gas…the list is extensive.

Can I add EAM to the existing ERP?

Yes. SAP, Oracle, and NetSuite have EAM modules. Alternatively, you can implement best-of-breed solutions and integrate via API.

Is cloud EAM safe?

Encryption, role-based access, automatic backups, multi-region hosting, and compliance certifications (ISO 27001, SOC 2, HIPAA) are some of the solutions offered by several modern EAM providers.

How long does implementation take?

Depending upon the size, implementation will typically take 3-12 months. A pilot or single plant can go live in 8-16 weeks, while enterprise roll-outs might be a year or longer.

What size company needs EAM?

You should be contemplating EAM when managing 200+ assets across sites or having an annual maintenance spend of $500K+.